Leading 100% Key Technologies

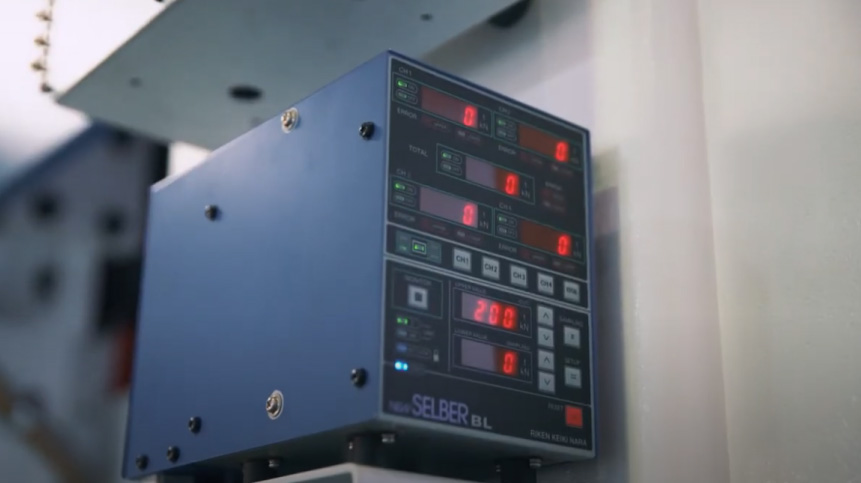

Electrical Control System

We have independently developed the APHA-PLC control system, enriching our electrical control system with inclusivity.

In the aspect of electrical control systems, we have independently developed the APHA-PLC control system. It is compatible with various brands of frequency converters and can be adjusted for stamping control modes based on customer requirements. The system is equipped with self-detection of faults and fault display capabilities, providing significant assistance in establishing a large-scale production database for Industry 4.0.

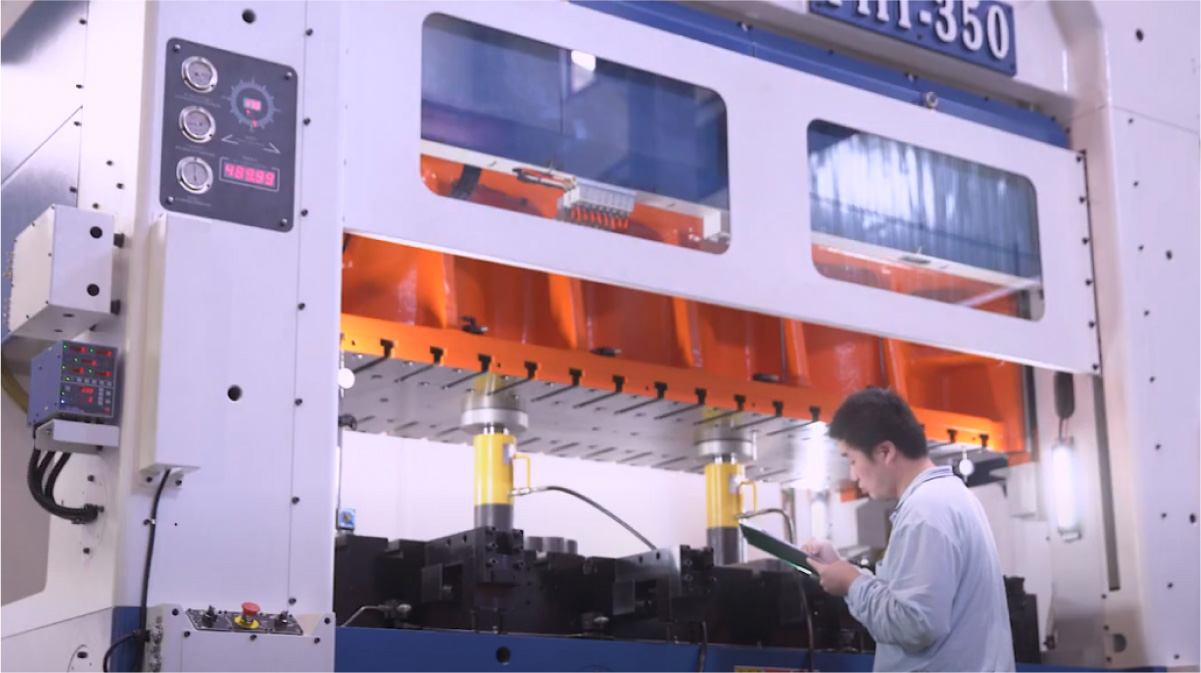

Turnkey Project for Stamping Production Line

Stamping Production Line Turnkey Project is another major business focus for us, in addition to regular product manufacturing.

We also support customers in planning turnkey projects for stamping production lines, providing FAIR OAKS's self-made full-process production lines, including presses, uncoilers, straighteners, feeders, stamping control systems, scrap trimmers, in-die riveting systems, etc.

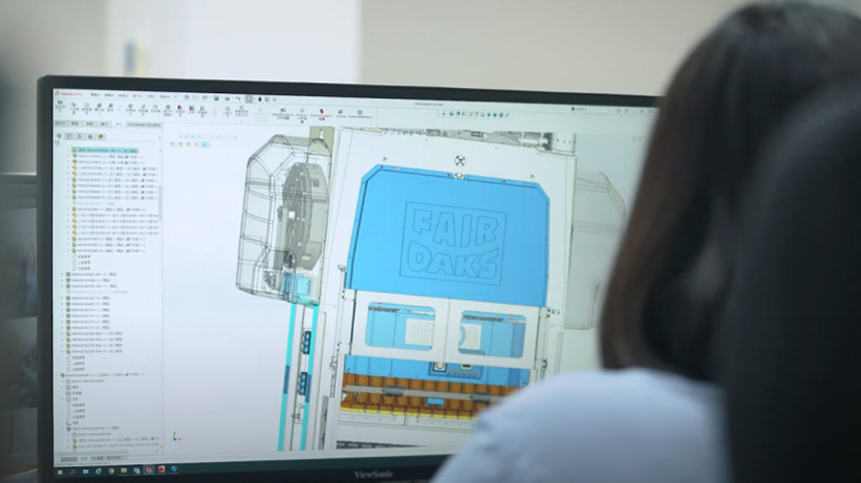

Brand Integration

Brand integration is one of the key aspects of the manufacturing process. We can assist customers in integrating existing production equipment.

FAIR OAKS has the capability to integrate customized production lines, allowing for the integration of production lines based on customer-specified peripheral equipment and other brands.

Quality Assurance

Internal Process Inspection

Multiple process inspections, including precision testing of transmission shafts, ensure the highest level of product accuracy across a wide range.

In terms of quality control, we have multiple processes in place. Internal process inspection serves as our self-checking protocol, covering items such as precision testing of transmission shafts, static assembly precision calibration of machines, fastening of machine locking screws, and more. Each step is marked for repeated verification, and torque wrenches are employed for secure tightening.

Crankshaft Inspection

Crankshaft inspection involves various measurements such as eccentricity measurement of the crankshaft and measurement of assembly positions at various crankshaft locations, ensuring the highest quality of the spindle.

In spindle inspection testing, we conduct measurements such as eccentricity measurement of the spindle crankshaft, measurement of assembly positions at various crankshaft locations, including linkage position assembly gap measurement, connecting rod gap measurement, flange gap measurement, dynamic balancing connecting rod gap measurement, and more.

Incoming Material Inspection

Incoming material inspection, including seven major items such as slider measurement and workbench measurement, ensures product quality.

Incoming material inspection includes IQC (Incoming Quality Control), inspection records for mechanical parts, acceptance of qualified goods into inventory after individual inspection, slide measurement, bolster measurement, crankshaft measurement, upright seat measurement, hardness testing, and surface roughness evaluation.

Process Inspection

Process inspection, involving various items such as crankshaft measurement and upright seat measurement, ensures that the product manufacturing process complies with international standards.

Process inspection: Key component measurements for IPQC are conducted in the constant temperature quality control room. There is secondary inspection during assembly, including slide measurement, crankshaft measurement, and upright seat measurement.

Pre-Shipment Quality Inspection

Pre-shipment quality inspection includes various measurements such as parallelism, straightness, ensuring the best product quality for customers.

Pre-shipment quality inspection includes FQC (Final Quality Control) inspection of 100% of finished products. Production serial numbers are tested using the international JIS (Japanese Industrial Standards) precision inspection standard. Parallelism, straightness, perpendicularity, and overall clearance are tested dynamically using a 4-point method at the dead center. Additionally, a no-load test of 1 million operating cycles is conducted on the entire machine.

Shipping Inspection

In the final shipping inspection, we deliver our products to customers with the utmost rigor and attention to detail.

Our shipping inspection checklist includes sealing of the box, documentation, nameplates, specification sheets, and other standard procedures. This ensures that even at the final moment of leaving our factory, our products still receive the utmost attention to detail.

High Cost Performance

The mechanical lifespan can reach up to 20 years

Machinery produced by ABC Company ensures precision and quality, with a long lifespan.

The entire machine adopts a forced lubrication and cooling system. This not only reduces the thermal deformation of the mechanism and components but also ensures the quality of stamped workpieces. It extends the mechanical lifespan and comes with a pressure detection warning function, equipped with a pressure detector and PLC display. Furthermore, the machine employs a fully-bearing power transmission system, where rolling transmission effectively reduces part wear, prolonging the operational life. In normal usage conditions, the crankshaft of FAIR OAKS's machine can guarantee a lifespan of over 20 years.

Fault Detection

The machine's fault detection includes various items such as cooling and pressure locking, which effectively reduce mechanical failure rates.

The machine is equipped with proactive fault detection functions, including monitoring of the cooling system, clamping pressure, air pressure monitoring, and prompts for fault troubleshooting methods, chip ejection, misdelivery monitoring, abnormal operation procedure alerts, etc. These features help reduce part damage rates and increase the lifespan of molds.

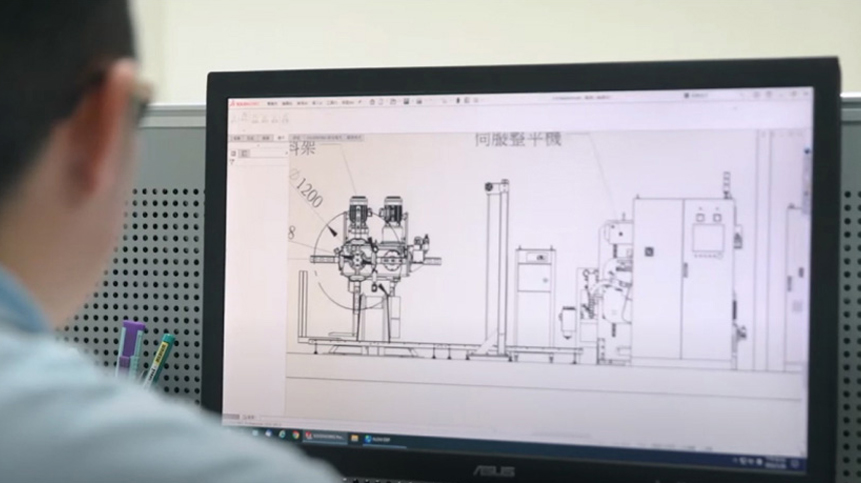

Production Line Planning

We have over 20 years of experience in manufacturing stamping production lines, and we have great confidence in our ability to plan efficient production lines.

Production Line Planning Consultation is one of our service strengths because FAIR OAKS has over 20 years of experience in standard stamping production lines as well as custom production line planning and manufacturing. Whether clients have stamping equipment and production experience or not, FAIR OAKS can provide planned production line cases for reference, assisting in their development. Such services can meet the satisfaction criteria of price and high cost-effectiveness, promoting cooperation.

Customized Production Manufacturing

In the field of stamping, customized production manufacturing represents a high-level test of comprehensive application and integration capabilities. With years of experience, FAIR OAKS can seamlessly tailor production planning to meet the needs of customers.

As long as customers can clearly provide the requirements for special product styles or production equipment, FAIR OAKS can quickly provide production line schematics within 2 weeks for customers to review and confirm.

After-sales Service

After-sales Service

Comprehensive after-sales service goes beyond establishing a database for standard spare parts. We also have a global service network that is sufficient to meet the needs worldwide.

FAIR OAKS's machines use a fully bearing-based power transmission method, making bearing replacement relatively simple and fast. Our entire range of equipment has established a database for standard spare parts, allowing us to promptly address customer needs for spare parts and subsequent product services.

After the equipment from ABC is delivered, the original manufacturer provides a one-year warranty, excluding human factors and natural disasters. Additionally, we offer 24/7 real-time consultation services, ensuring that customers from anywhere in the world can receive effective and immediate assistance. Our sales and installation locations are spread across the globe, including Turkey, mainland China, Vietnam, India, and more.