Company Profile

About Us

FAIR OAKS PRECISION MACHINERY (F) CO., LTD, founded in 1995 and originally located in Daya District, Taichung City, specializes in the production of high-speed precision presses and peripheral equipment. In 2012, the company relocated to Shengang District, Taichung City, where its factory now spans nearly 6000 ping (213540 square feet). Over the past two decades, through the concerted efforts of all FAIR OAKS employees, the company has emerged as one of the leading manufacturers of high-speed precision presses in Taiwan. Marketed under its proprietary brand "FAIR OAKS" the company has gained recognition worldwide. Renowned for its commitment to high quality and professional expertise, FAIR OAKS Corporation has earned acclaim within the industry. Its high-speed precision presses, integrating advanced technology, are widely acclaimed by domestic and international customers for their outstanding performance.

FAIR OAKS Corporation boasts a robust technical team, enabling us to continuously innovate and break through in terms of technology. The manufacturing and inspection of presses strictly adhere to rigorous quality standards, with professional quality control personnel conducting strict inspections on parts entering the factory and throughout the manufacturing process, ensuring the highest level of quality. With our outstanding technical capabilities, FAIR OAKS is able to provide high-speed precision presses that meet the demands of our customers.

Design Philosophy

Only by continuously improving production technology can we meet customer demands and secure a place in the fiercely competitive market. FAIR OAKS precision presses are designed and manufactured using advanced stamping technology, adhering to the principles of "high speed, precision, and longevity." Therefore, the precision presses produced by FAIR OAKS possess the following characteristics:

Stable Structure

The machine's castings are made of high-strength cast iron, which undergo stress relief to ensure long-term accuracy, and the "Computerized finite element analysis" is employed. Therefore, the strength and strain of the structure can be ensured for optimal design.

High Precision

Before assembly by professional personnel, all parts undergo strict quality control, and all presses meet the JIS Special standard.

Low Vibration, Low Noise

Excellent dynamic balance design minimizes vibration and noise while ensuring Stamping die longevity.

Ease of Operation

Advanced computer controllers, utilizing uniquely developed stamping operation software, guide parameter settings for machine configuration. This makes mechanical operation more straightforward. Additionally, it features fault display functionality, allowing customers to troubleshoot and resume production in the shortest possible time.

Future Outlook

- To manufacture the safest, most efficient, and best quality presses equipment brand, and constantly innovate and transform products to inspire and promote the improvement of the environmental crisis, and to become an international model for the sustainable development of the Press industry.

- With integrity, quality first, customer-oriented, respect for individuals, team spirit, social responsibility, become a pioneer in the industry, create the most trusted products for customers, devote ourselves to product innovation, and create value and glory for working partners and customers.

- High will continue to strive towards internationalization in marketing. Adhering to the business philosophy of "service first, quality supreme," we aim to carefully understand customer issues, address specific needs across various industries, enhance research and development, and create new products. We hope to progress and grow together with our customers, achieving a win-win situation.

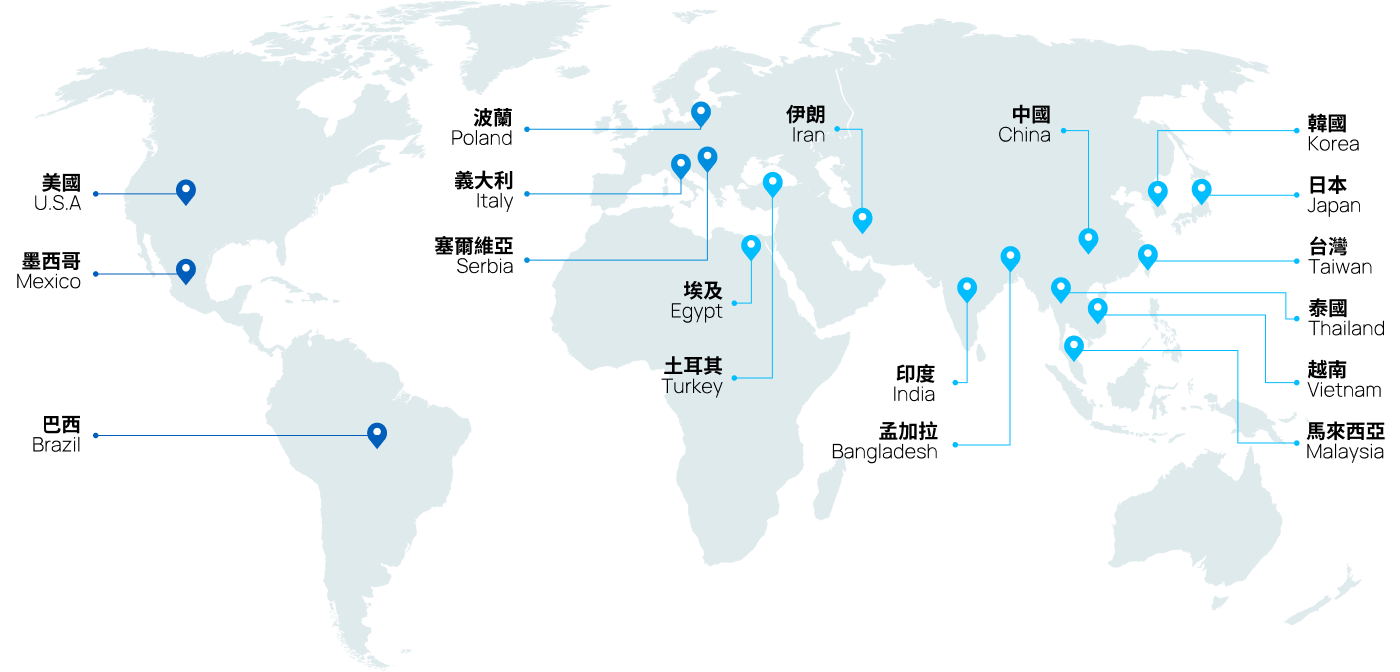

Global Marketing

Selling to more than 17 countries

Asia

Japan India Korea Iran Bangladesh Egypt Malaysia Turkey Thailand China Vietnam TaiwanEurope

Italy Poland SerbiaAmerica

U.S.A Mexico BrazilGlobal Dealer

INDIA

M/s. SAKAR ENGINEERS

D-903, Raikar Chambers, Deonar Village Road, Govandi (East)- 400088

Cell-Phone: 919022408857

E-mail: sales01@sakar-engineers.co.in

M/s. TVENKA TECHNOLOGIES

6,Spartan Avenue ,Mogappair East ,Chennai – 600 037.

Cell-Phone:919840940913

E-mail: info@tvenka.com ; mtm@tvenka.com

TURKEY

GENERAL MAKINA

lkitelli OSB. Metal Is San. Sit. 16 Blok No.1 Basaksehir/Istanbul/Turkiye

Tel:90-212 671 97 18-19 / Fax:90-212 671 97 27 GSM:+90 532 435 27 84

E-mail: levent@generalmakina.com.tr

http://www.generalmakina.com.tr

EGYPT

Canova International Limited Company

242045新北市新莊區榮華路一段3號5樓

Tel: +886-2-85217533/Fax: +886-2-85217571

Mobile: +886-958081368

Email: eddiekao@canova.com.tw

Bulgaria

MILCO Ltd.

Bulgaria, 4230 Asenovgrad, 11 Kozanovska Str.

Tel: 359 331 64040, 65050, 67070 / Fax: 359 331 63030

Email: info@milco.bg